Descriptions

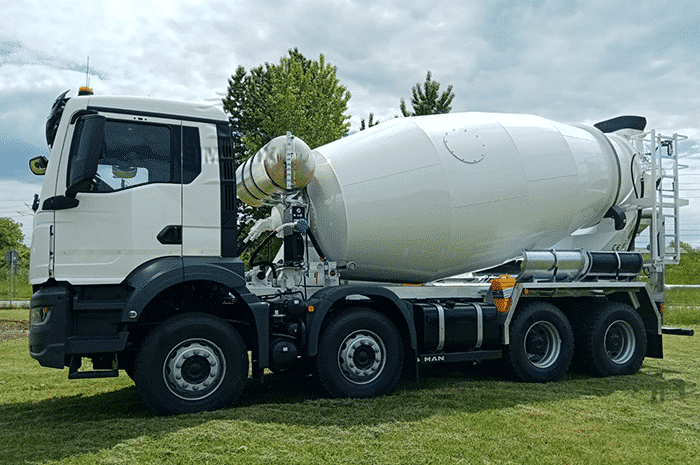

Concrete mixer truck 18 cubic meters is a special truck used to transport concrete for construction.

Because of its shape, it is often referred to as a field snail truck.

These trucks are equipped with cylindrical stirrer to carry mixed concrete.

In the course of transportation, the mixing drum will always be rotated to ensure that the concrete carried will not solidify.

After the concrete is transported, the inner part of the mixing drum is usually flushed with water to prevent the hardening of the concrete from occupying space, so that the volume of the mixing drum will not become smaller and smaller.

Because of its shape, it is often referred to as a field snail truck.

These trucks are equipped with cylindrical stirrer to carry mixed concrete.

In the course of transportation, the mixing drum will always be rotated to ensure that the concrete carried will not solidify.

After the concrete is transported, the inner part of the mixing drum is usually flushed with water to prevent the hardening of the concrete from occupying space, so that the volume of the mixing drum will not become smaller and smaller.

Features

Excellent mixing performance

The rotating direction of mixing stars is reversed with the revolution direction, and each mixing star’s direction is also different.

There are both circulation movement and convective movement during material mixing, which makes the material severely mixed.

The counter current and impact prevent material from agglomeration and thoroughly mixed and achieve the uniform distribution in microcosm.

High mixing efficiency, low energy consumption

The new concept of counter-current mixing makes the mixing tracks more complex, mixing effects more severe and effective.

In the condition of same material proportion and same feeding order, the innovated planetary mixer’s mixing time is shortened by 15-20% compared to traditional models.

The innovated power driving design and optimized mixing device are of high transmission efficiency; both the no-load current load current are lower by 15-20% compared to traditional planetary mixers.

Optimized mixing device design

Optimized mixing blades and installation angle, and improved mixing arm make the mixing motion more effective.

The load distribution of gearing system is more reasonable, the discharging faster and cleaner, effectively avoiding material sticking and material deposit.

Multiple rotate-speed configurations

Multiple-rotate-speed gearing device can deal with different materials and conditions.

The gearing configuration is only adjusted inside the reducer.

The appearance and connecting part are universal, which makes the mixer’s application wider.

.jpg)

The rotating direction of mixing stars is reversed with the revolution direction, and each mixing star’s direction is also different.

There are both circulation movement and convective movement during material mixing, which makes the material severely mixed.

The counter current and impact prevent material from agglomeration and thoroughly mixed and achieve the uniform distribution in microcosm.

High mixing efficiency, low energy consumption

The new concept of counter-current mixing makes the mixing tracks more complex, mixing effects more severe and effective.

In the condition of same material proportion and same feeding order, the innovated planetary mixer’s mixing time is shortened by 15-20% compared to traditional models.

The innovated power driving design and optimized mixing device are of high transmission efficiency; both the no-load current load current are lower by 15-20% compared to traditional planetary mixers.

Optimized mixing device design

Optimized mixing blades and installation angle, and improved mixing arm make the mixing motion more effective.

The load distribution of gearing system is more reasonable, the discharging faster and cleaner, effectively avoiding material sticking and material deposit.

Multiple rotate-speed configurations

Multiple-rotate-speed gearing device can deal with different materials and conditions.

The gearing configuration is only adjusted inside the reducer.

The appearance and connecting part are universal, which makes the mixer’s application wider.

.jpg)

Parameter

| 【truck parameters】 | |||||

| Product name | Concrete mixing truck | ||||

| Total weight(Kg) | 31000 | capacity(m3) | 18 | ||

| Rated loading weight(Kg) | 11870 | Outlet dimension(mm) | 11970×2500,2550×3990 | ||

| Equipment weight(Kg) | 19000 | Numbers in the cab(人) | 2 | ||

| Approach/departure angle(°) | 16/19 | Front overhang/rear overhang(mm) | 1500/3495,1500/3450 | ||

| Axle load(Kg) | 6500/7000/17500 (two-axis group) | Maximum speed(Km/h) | 80 | ||

| 【chassis parameters】 | |||||

| Chassis number | ZZ1317N3867E1 | Chassis brand | HOWO | ||

| Number of axes | 4 | Tire No. | 12 | ||

| wheelbase (mm) | 1800+3825+1350 | ||||

| Tire specification | 12.00R20 18PR | ||||

| Number of leaf springs | 4/4/12 | Front track(mm) | 2022/2022,2041/2041 | ||

| fuel | diesel | back track(mm) | 1830/1830 | ||

| Emission standard | EuroⅤ | ||||

| Engine No. | manufacture | Displacement(ml) | power(Kw) | ||

| D10.38-50 | Sino truck | 9726 | 276 | ||

| Dedicated configuration |

Made of Q345 national standard high-strength wear-resistant manganese steel plate, [volume]: the tank volume is 18 cubic meters. [Hydraulic parts]: Install PMP reducer, Saao's oil pump and motor, add an enlarged toolbox, [Operating system]: Trinity operating system (the tank can be reversed on both sides of the cab and the rear of the vehicle to reduce the labor intensity of the operator and easy to operate). [Others]: The tank mixing blade is equipped with wear resistance (increasing the applicable life of the blade), and the wear and absorbing pad of the inlet and outlet hopper are lined with the wear pad (increasing the service life) and made by the arc-shaped mold (beautiful, and effectively reduce the aggregate), easy to clean), punching anti-skid ladder (effectively improve the safety of the operator), install LED after work lights and side lights (safe, environmentally friendly, energy saving). |

||||

If you are interested in our company or products, welcome to visit our company you can also get contact with us through online consulting,

E-mail: info@smachine1983.com and Telephones:+86 18538068019.

Service

1: Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2: Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3: Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem.

4: Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2: Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3: Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem.

4: Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

Successful cases

.jpg)

.jpg)

.jpg)