Description

JS series concrete mixers are double horizontal axle forced mixers with two advantages of independent performance or forming simple concrete mixing plants with PLD series of batching machines.

They can be used to mix dry hard concrete, plastic concrete, flow concrete, light aggregate concrete and various mortars, so they were popular in precast concrete plants, industrial and civil construction works, bridges, water works, roads, airport and harbors.

They can be used to mix dry hard concrete, plastic concrete, flow concrete, light aggregate concrete and various mortars, so they were popular in precast concrete plants, industrial and civil construction works, bridges, water works, roads, airport and harbors.

Main Machine

-

Twin Shaft Concrete MixerYHZS60 concrete batch plant adopts top-quality JS1500 twin shaft forceful concrete mixer, which features for quick and uniform mixing, high efficiency, wide mixing range and excellent-quality concrete, can fullest meet different producing requirement

Twin Shaft Concrete MixerYHZS60 concrete batch plant adopts top-quality JS1500 twin shaft forceful concrete mixer, which features for quick and uniform mixing, high efficiency, wide mixing range and excellent-quality concrete, can fullest meet different producing requirement -

Control SystemSMART mobile batching plant adopts microcomputer and operation-console double control system, having automatic, semi-automatic and manual three controlling modes. YHZS60 fully consider the concrete requirements, having the unique technologies of unique ratio deposit, storage, self-compensation of weighing fall and moisture, self-reversing of over-weighing and short-weighing, online modifying of formula, data recording, check, report, printing and so on.

Control SystemSMART mobile batching plant adopts microcomputer and operation-console double control system, having automatic, semi-automatic and manual three controlling modes. YHZS60 fully consider the concrete requirements, having the unique technologies of unique ratio deposit, storage, self-compensation of weighing fall and moisture, self-reversing of over-weighing and short-weighing, online modifying of formula, data recording, check, report, printing and so on. -

Pneumatic SystemPneumatic system adopts well-known Taiwan Fusheng air compressor, which is of high configuration, high reliability, high intellectualization and economic running, providing sufficient air supplying for the entire concrete mixing plant.

Pneumatic SystemPneumatic system adopts well-known Taiwan Fusheng air compressor, which is of high configuration, high reliability, high intellectualization and economic running, providing sufficient air supplying for the entire concrete mixing plant. -

Aggregate Batching and Weighing SystemSmart PLD series aggregate batching machine adopt electronic weighing, microcomputer control, digital display, possessing the features of accurate weighing, high precision, quick running, powerful controlling and so on. According to the producing and customer’s requirement, we have separate weighing and accumulate weighing for choice, and recommend customers the most suitable batching machine according to practical condition.

Aggregate Batching and Weighing SystemSmart PLD series aggregate batching machine adopt electronic weighing, microcomputer control, digital display, possessing the features of accurate weighing, high precision, quick running, powerful controlling and so on. According to the producing and customer’s requirement, we have separate weighing and accumulate weighing for choice, and recommend customers the most suitable batching machine according to practical condition.

If you are interested in our company or products, welcome to visit our company you can also get contact with us through online consulting,

E-mail: info@smachine1983.com and Telephones:+86 18538068019.

Feature

- HZS75 concrete batching plant, whose production capacity is 75m3/h, flexibly consists of JS1500 twin shaft concrete mixer,

- PLD2400 batching machine, cement silos, control system and relevant equipment.

- On the other hand, the JS1500 twin shaft concrete mixer, compulsory and efficient,

- can work independently. This kind of 75m3 concrete batch plant is of simple structure, easy installation and disassembling,

- convenient construction, widely applied to various big and middle industry and civil construction of bridge,

- highway, water conservancy project and wharf and so on. HZS75 cement batching plant, capable of excellent mixing hard-dry concrete,

- light aggregate concrete and various mortars, is an ideal equipment to produce commercial concrete.

Spare Parts

Hi-Chrome Iron castings with Brinell hardness of 650+ for shovels and wear plates. Other parts like mixing arms are manufactured from alloy steel castings. The exceptional hardness of these castings achieved by long Heat treatment cycles extends its wear life.super quality method and equipments enable us to produce Ni-Hard, Hi-Chrome Iron castings with Brinell hardness of 650+ for shovels and wear plates. Other parts like mixing arms are manufactured from alloy steel castings.

High precise ratio of metal composition; accurate designed screw hole position, lost foam casting art, high wear resistance. Customized design wear very welcomed!

Liners. Wear Plates, Mixing arms, Mixing Blades. Mixing paddles, scrapers, wear plate for outer wall,wear plate for inner wall and all types of concrete and cement mixer liners.

High precise ratio of metal composition; accurate designed screw hole position, lost foam casting art, high wear resistance. Customized design wear very welcomed!

Liners. Wear Plates, Mixing arms, Mixing Blades. Mixing paddles, scrapers, wear plate for outer wall,wear plate for inner wall and all types of concrete and cement mixer liners.

If you are interested in our company or products, welcome to visit our company you can also get contact with us through online consulting,

E-mail: info@smachine1983.com and Telephones:+86 18538068019.

Service

1. Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

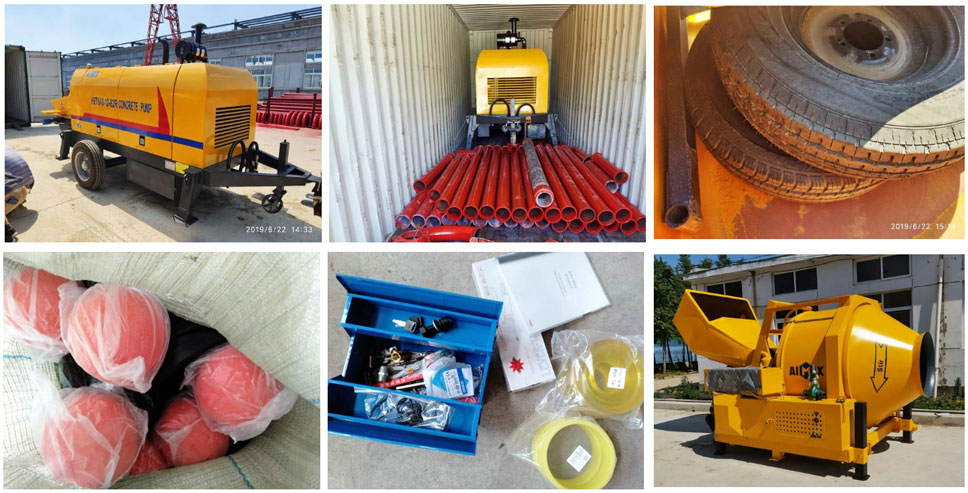

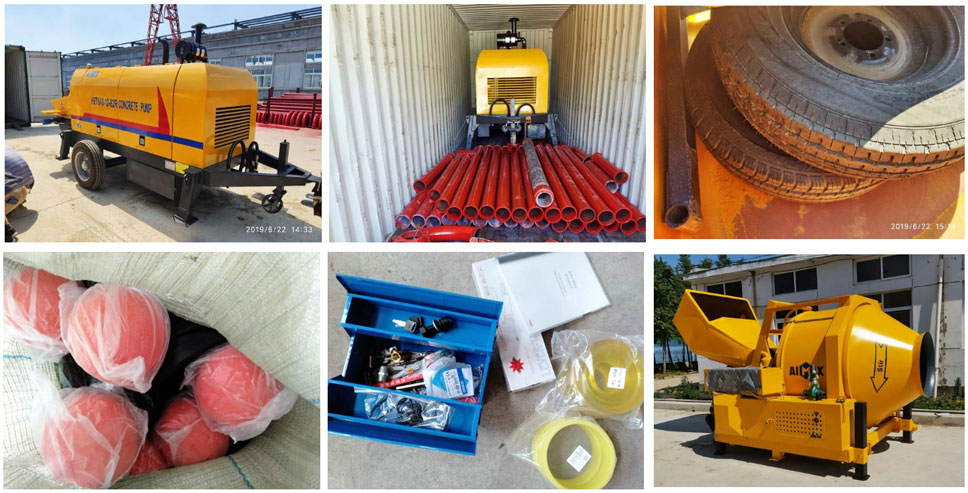

2. Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3. Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4. Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2. Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3. Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4. Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

Successful cases

.jpg)

.jpg)

.jpg)