DETAILS

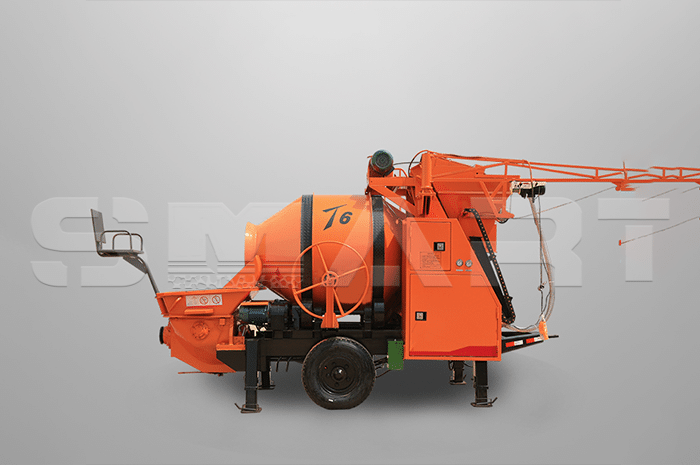

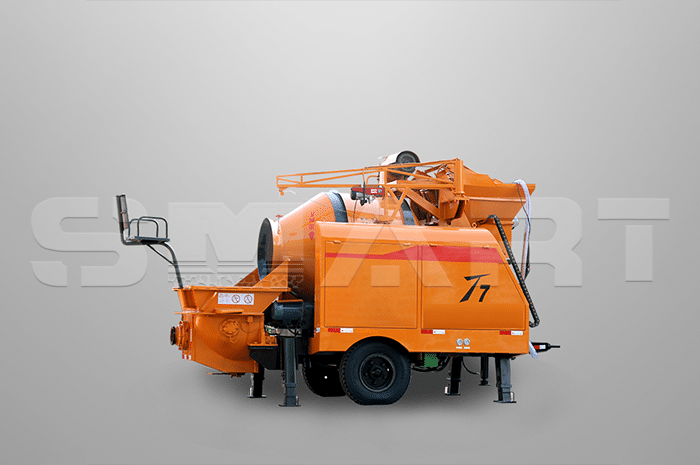

Concrete Pump STG-T Series

- SIMAMIX has independently designed and developed a new generation of mobile mixing plant series to meet different construction needs and industry standards.

- In 2021, SIMAMIX introduced the STG-T series mixing trailer pump, bringing a brand-new solution to the market.

- The STG-T mixing trailer pump is the seventh generation luxury configuration product independently developed by SIMAMIX, combining advanced technology with exquisite craftsmanship.

- This product has comprehensive advantages in terms of high configuration, complete functions, good performance, and attractive appearance, which can meet the diverse needs of users.

- The strong conveying capacity is a highlight of the STG-T mixing trailer pump: the vertical pumping distance can reach 50-70 meters, and the horizontal pumping distance can reach 250-350 meters, ensuring efficient and smooth operation of construction.

- The efficient hydraulic system is the core of this product: it adopts imported Kawasaki pump and advanced hydraulic system to provide more stable and reliable performance.

- Safer construction is one of the important advantages of the STG-T mixing trailer pump: compared with traditional equipment, it can easily handle heights of up to 20 floors when pumping concrete, while traditional equipment becomes quite dangerous when pouring above the 4th floor.

- High level of automation is another highlight of this product: only 4-5 people are needed to easily complete the entire process of feeding, mixing, and pumping, greatly improving construction efficiency.

- In addition, the STG-T mixing trailer pump also has the function of pumping large aggregates, which can meet the needs of special engineering projects.

PARAMETERS

| Item | T6 | T7 | T8 | T9 |

|---|---|---|---|---|

| Maximum Outlet Pressure | 8 Mpa | 8 Mpa | 8 Mpa | 8 Mpa |

| Concrete Delivery Capacity | 30 m³/h | 30 m³/h | 30 m³/h | 30 m³/h |

| Main Motor Power | 30/37 KW | 30/37 KW | 30/37 KW | 53 KW |

| Theoretical Transmission Distance | 350 m / 70 m | 350 m / 70 m | 350 m / 70 m | 350 m / 70 m |

| Maximum Granule of Aggregate | 40 mm | 40 mm | 40 mm | 40 mm |

| Slump of Concrete | 140~230 mm | 140~230 mm | 140~230 mm | 140~230 mm |

| Conveying Cylinder | φ200 * 800 mm | φ200 * 800 mm | φ200 * 800 mm | φ200 * 800 mm |

| Drum Mixer (Model) | 450 | 450 | 450 | 450 |

| Hopper Volume | 0.7 m³ | 0.7 m³ | 0.7 m³ | 0.7 m³ |

| Totally Weight | 5.5 Ton | 5.8 Ton | 5.8 Ton | 6.2 Ton |

| Size (H * L * W) | 5200*2200*3350 mm | 5200*2200*3350 mm | 5200*2200*3350 mm | 5300*2200*3350 mm |

COMPANY PROFILE

Zhengzhou Smart Machinery Manufacturer Co., Ltd. was established in 1990. It is an enterprise mainly specializing in the research and development, manufacturing and sales of construction machinery including concrete mixing plants, concrete block production lines, etc.

The factory is located in Henan Province, China, covering an area of 126,000 square meters, with 50 professional engineers and 200 workers. After more than 30 years of continuous innovation and hard work, products have been sold all over the world and are well received by domestic and abroad users, including more than 100 countries and regions: Philippines, Cambodia, Malaysia, Kazakhstan, Uzbekistan, Mongolia, Russia, Colombia, Ecuador, South Africa and so on, and set up an office in Cambodia, with a sound, complete, and huge sales network system.

We can provide customers with the highest quality solutions and production to meet customers' needs for different products, at the same time, we can provide a full range of turnkey projects: equipment installation, commissioning, maintenance and training.

High-quality service, advanced technology, sophisticated equipment, and strict management are the foundation reason for company's continuous development and products that can win the support of users. We have won foreign customers’ trust and praise with perfect and professional pre-sales, in-sales, and after-sales services.

The factory is located in Henan Province, China, covering an area of 126,000 square meters, with 50 professional engineers and 200 workers. After more than 30 years of continuous innovation and hard work, products have been sold all over the world and are well received by domestic and abroad users, including more than 100 countries and regions: Philippines, Cambodia, Malaysia, Kazakhstan, Uzbekistan, Mongolia, Russia, Colombia, Ecuador, South Africa and so on, and set up an office in Cambodia, with a sound, complete, and huge sales network system.

We can provide customers with the highest quality solutions and production to meet customers' needs for different products, at the same time, we can provide a full range of turnkey projects: equipment installation, commissioning, maintenance and training.

High-quality service, advanced technology, sophisticated equipment, and strict management are the foundation reason for company's continuous development and products that can win the support of users. We have won foreign customers’ trust and praise with perfect and professional pre-sales, in-sales, and after-sales services.

If you are interested in our company or products, welcome to visit our company you can also get contact with us through online consulting,

E-mail: info@smachine1983.com and Telephones:+86 18538068019.

SERVICE

1. Guarantee Time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2. Free Spare Parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3. Technical Supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4. Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2. Free Spare Parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3. Technical Supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4. Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

.jpg)