Concrete Brick Machine QT4-25 is the big brick machine with simple structure and convenient operation. It is powered by the hydraulic press. It can be made into hollow bricks, solid bricks, paving bricks and other brick types.

The non-burning brick machine is a kind of brick making machine equipment. In the process of producing bricks, it is different from the traditional kiln brick making process. It is formed by hydraulic pressure and does not require firing engineering.

It has the characteristics of compact structure, large pressing force, strong rigidity, fully sealed dustproof, circulating lubrication, simple operation, high output and durability.

The non-burning brick machine adopts advanced technology in the feeder variable speed and rotary table rotation, which has the advantages of large transmission force, stable operation, accurate in place, and low maintenance rate.

2. When pressing, and computer controlled directional vibration, frequency and brake to cancel the vibration energy.

3. Hopper installed a swing-type cutting device, it can put the materials into the molding box uniformly by adjusting the swinging fork.

4. The host keeping material controlled by photoelectric, material that is used upon to avoid the impact of aftershocks, some concrete liquefied advance.

5. Feeding in low-frequency, vibrating in high frequency, and increasing in Head tanks. Table and mould vibrating together will make concrete fully liquefied and exhausted in 2-3 seconds to achieve high-density and high strength. Particularly be suitable for the production of high-strength blocks, you can stack immediately after forming.

| Overall dimension | 6400x1600x2500mm |

| Cycle time | 15-25 seconds |

| Power | 26.45 KW |

| Weight | 4000kgs |

| Pallet size | 900x550mm |

| Rated pressure | 16Mpa |

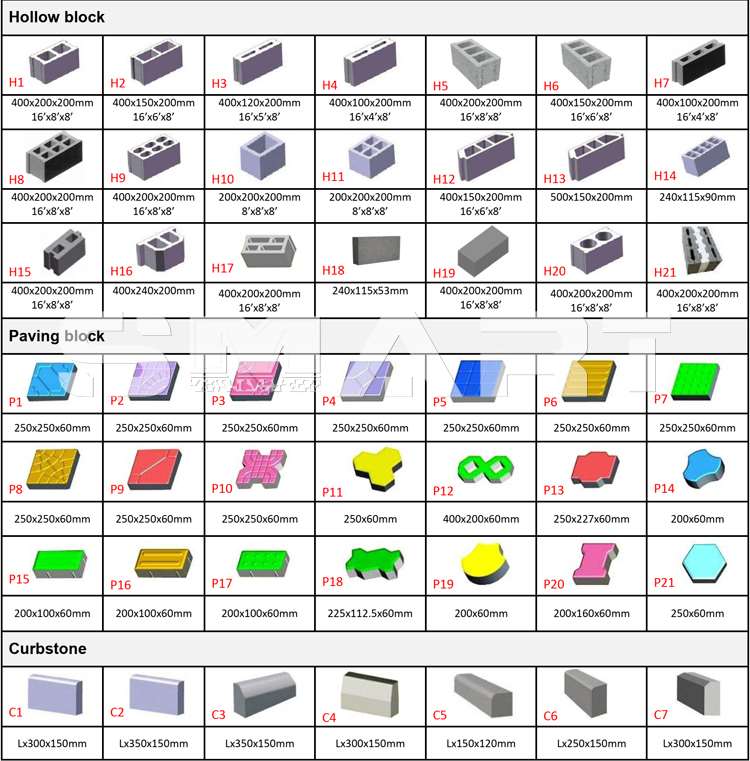

Block machine sample

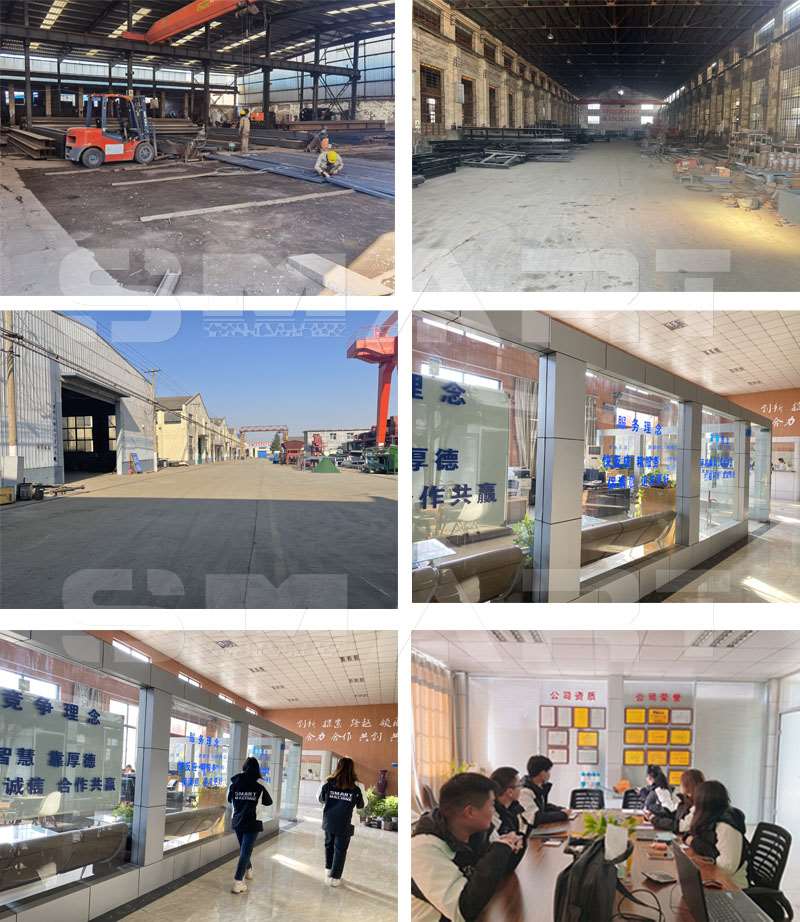

Zhengzhou Smart Machinery Manufacturer Co., Ltd. was established in 1990. It is an enterprise mainly specializing in the research and development, manufacturing and sales of construction machinery including concrete mixing plants, concrete block production lines, etc.

The factory is located in Henan Province, China, covering an area of 126,000 square meters, with 50 professional engineers and 200 workers. After more than 30 years of continuous innovation and hard work, products have been sold all over the world and are well received by domestic and abroad users, including more than 100 countries and regions: Philippines, Cambodia, Malaysia, Kazakhstan, Uzbekistan, Mongolia, Russia, Colombia, Ecuador, South Africa and so on, and set up an office in Cambodia, with a sound, complete, and huge sales network system.

We can provide customers with the highest quality solutions and production to meet customers' needs for different products, at the same time, we can provide a full range of turnkey projects: equipment installation, commissioning, maintenance and training.

High-quality service, advanced technology, sophisticated equipment, and strict management are the foundation reason for company's continuous development and products that can win the support of users. We have won foreign customers’ trust and praise with perfect and professional pre-sales, in-sales, and after-sales services.

Packing & Delivery

Our Service

1.Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2.Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3.Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4.Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

.jpg)

.jpg)

.jpg)