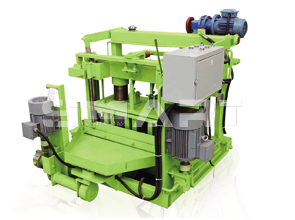

Concrete brick machine QT10-15 is the big brick machine with simple structure and convenient operation. It is powered by the hydraulic press. It can be made into hollow bricks, solid bricks, paving bricks and other brick types.

1. QT10-15 fully moulds concrete brick block making machine can produce various solid blocks , hollow blocks, pavers and curbstones by changing moulds.

2. QT10-15 fully moulds concrete brick block making machine adopt to hydraulic pressure moulding system , so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density and higher strength.

3. Precise line cutting technology and carburizing treatment technology to prolong mould life and increase precision of the block.

4. Switches will use Japan Omron or France Schneider band, motor will use Siemens or ABB brand.

Features

1.The machine adopts hydraulic system and the working procedure is very even and dependable,

2. It is a practical machine that simple in structure, artistic in figure.

3.Especially suitable to the production of the standard bricks

4. The reasonable material proportion have the capacity of making highdensity standard bricks.

|

Dimension of host machine |

3500 *2300 *2930mm |

|

Moulding area |

1196*880mm |

|

Moulding cycle |

15s |

|

Pallet size |

1300*900*30mm |

|

Host machine power |

37kw |

|

Weight |

9.8T |

|

Viration force |

100KN |

|

Mixer modeal |

JS750 |

|

Voltage |

220V/380V/440V |

|

Water consumption |

10-20T/day |

Mixing Sytem

The JS series concrete mixer is a double-horizontal-shaft compulsory mixer. This machine has the two advantages of a stand-alone operation and a simple mixing station with the PLD series batching machine. It is a high-efficiency model with a wide range of applications.Stir evenly and thoroughly, without residue, simple structure, simple operation, fast discharging speed, sturdiness and durability, long service life, and convenient maintenance.

PLC Control System

Control the operation of the concrete block automatic machine: feeding, shaking, pressing, sending, and other operating instructions. Programmable Logic Controller, intelligent control system. There are two modes: automatic mode and manual mode, one-key conversion, the unmanned operation can be realized.PLC is a remote control system for replaying relays, executing logic and other sequence control Advantages: PLC has strong versatility, convenient use, wide adaptability, high reliability, and strong anti-interference ability.

Very convenient and easy to operate. The hydraulic station of concrete block machine maker provides power support for the brick machine production line, so that the brick machine can run faster.

.jpg)

Mold

The mold of the brick machine is an indispensable part of product production. Used as a model to produce various styles of bricks. Using heat treatment and carburizing technology, the processed mold has higher hardness, more wear resistance, and longer service life.

In addition, the mold of the brick machine can be customized according to the needs of customers, just need to give the shape and size of the brick.

.jpg)

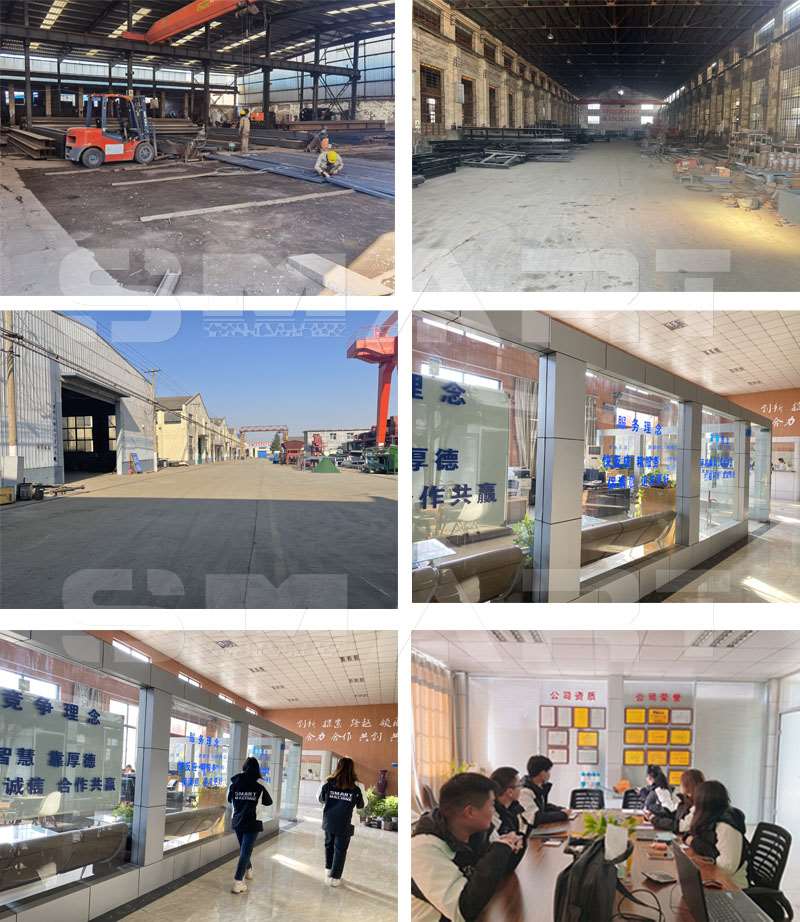

Zhengzhou Smart Machinery Manufacturer Co., Ltd. was established in 1990. It is an enterprise mainly specializing in the research and development, manufacturing and sales of construction machinery including concrete mixing plants, concrete block production lines, etc.

The factory is located in Henan Province, China, covering an area of 126,000 square meters, with 50 professional engineers and 200 workers. After more than 30 years of continuous innovation and hard work, products have been sold all over the world and are well received by domestic and abroad users, including more than 100 countries and regions: Philippines, Cambodia, Malaysia, Kazakhstan, Uzbekistan, Mongolia, Russia, Colombia, Ecuador, South Africa and so on, and set up an office in Cambodia, with a sound, complete, and huge sales network system.

We can provide customers with the highest quality solutions and production to meet customers' needs for different products, at the same time, we can provide a full range of turnkey projects: equipment installation, commissioning, maintenance and training.

High-quality service, advanced technology, sophisticated equipment, and strict management are the foundation reason for company's continuous development and products that can win the support of users. We have won foreign customers’ trust and praise with perfect and professional pre-sales, in-sales, and after-sales services.

Packing & Delivery

Our Service

1.Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2.Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3.Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4.Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

.jpg)

.jpg)

(1).jpg)