Features

1: Raw materials: sand, stones, cement, fly ash, slag industrial wastes, construction waste, etc. Can realize diversified environmental protection.

2: The production line is mainly composed of batching mixing system, block forming, lifting plate system, palletizing and feeding system and fully automatic centralized control system.

3: Fully automatic concrete brick machine adopts platform vibration and hydraulic forming methods, widely used in roads, parks, urban construction, etc.

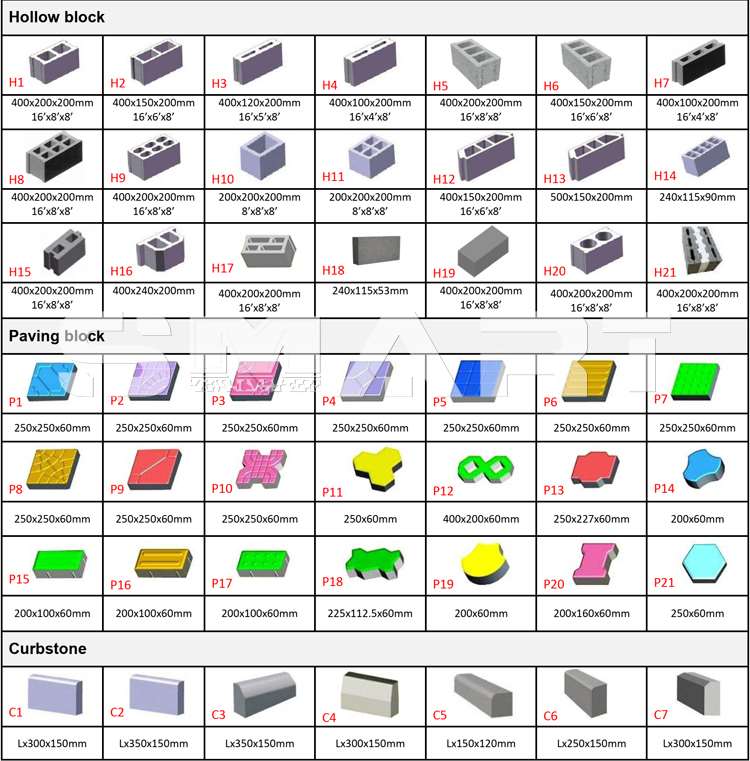

4: Molds can be customized to produce hollow bricks, solid bricks, pavement bricks, etc. With the addition of a secondary adding color device, can produce various colorful grass-planting bricks and slope protection bricks.

Advantages:

1. Compact and reasonable layout: saving floor space.

2. Simple operation, stable and reliable performance.

3. High flexibility, molds can be customized to meet individual needs.

4. High economic applicability: small investment and large return.

5. Unique storage and distribution design, accurate dosage and good consistency of product density.

Large models brick machines

| Features | Multifunction | Model | Capacity | Power |

Fully Automatic Hydraulic Press Automatic Feeding Material Automatic Feeding Pallet |

Hollow Block Solid Block Pavers Curbstone |

QT12-15 | 17280pcs Per 8h | 50.88KW |

| QT10-15 | 14400pcs Per 8h | 46KW | ||

| QT8-15 | 11520pcs Per 8h | 36.65KW | ||

| QT6-15 | 8640pcs Per 8h | 36.4KW | ||

| QT4-15 | 5760pcs Per 8h | 29.4KW |

Medium models brick machines

| Features | Multifunction | Model | Capacity | Power |

| Semi Automatic Hydraulic Automatic Feeding Material Automatic Feeding Pallet |

Hollow Block Solid Block Pavers Curbstone |

QT4-18 | 5760pcs Per 8h | 22KW |

| Semi Automatic Automatic Feeding Material Automatic Feeding Pallet |

QT4-25 | 4600pcs Per 8h | 16KW | |

| Semi Automatic Automatic Feeding Material Manual Feeding Pallet |

QT4-26 | 4600pcs Per 8h | 11.75KW | |

| Semi Automatic Manual Feeding Material Manual Feeding Pallet |

QT4-30 | 3840pcs Per 8h |

15HP | |

QT4-40 |

4800pcs Per 8h | 9.6KW | ||

| Small Manual Manual feeding material Manual feeding pallet |

QT40C-1 |

2800pcs Per 8h | 9.9KW | |

Movable Hydraulic No need Pallet |

Hollow/Solid Block | QMY6-25 | 6900pcs Per 8h | 11.2KW |

Small models brick machines

| Features | Multifunction | Model | Capacity | Power |

| Movable Diesel Power No need Pallet |

Hollow/Solid Block |

QMR4-45 | 2560pcs Per 8h | 10HP |

| Movable Electric Power No need Pallet |

QMY4-45 | 2560pcs Per 8h | 6.6KW | |

| Movable Hydraulic No need Pallet |

QT40-3A | 2560pcs Per 8h | 5.2KW | |

| Movable Electric Power No need Pallet |

QMR2-45 | 1280pcs Per 8h | 1.5KW |

Block machine sample

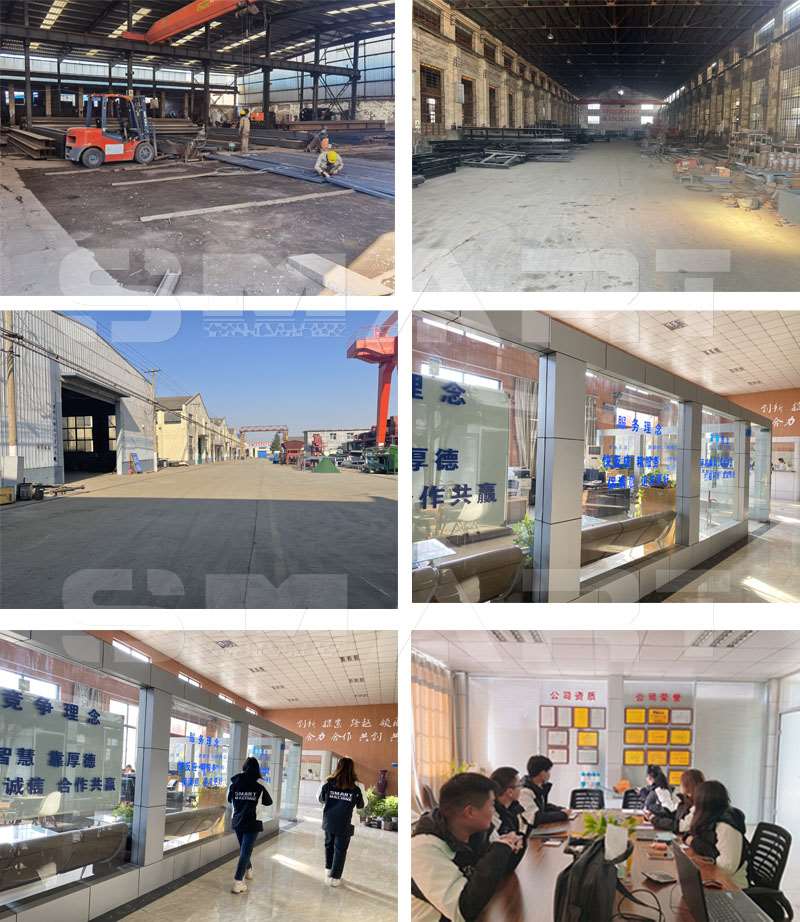

Zhengzhou Smart Machinery Manufacturer Co., Ltd. was established in 1990. It is an enterprise mainly specializing in the research and development, manufacturing and sales of construction machinery including concrete mixing plants, concrete block production lines, etc.

The factory is located in Henan Province, China, covering an area of 126,000 square meters, with 50 professional engineers and 200 workers. After more than 30 years of continuous innovation and hard work, products have been sold all over the world and are well received by domestic and abroad users, including more than 100 countries and regions: Philippines, Cambodia, Malaysia, Kazakhstan, Uzbekistan, Mongolia, Russia, Colombia, Ecuador, South Africa and so on, and set up an office in Cambodia, with a sound, complete, and huge sales network system.

We can provide customers with the highest quality solutions and production to meet customers' needs for different products, at the same time, we can provide a full range of turnkey projects: equipment installation, commissioning, maintenance and training.

High-quality service, advanced technology, sophisticated equipment, and strict management are the foundation reason for company's continuous development and products that can win the support of users. We have won foreign customers’ trust and praise with perfect and professional pre-sales, in-sales, and after-sales services.

Packing & Delivery

Our Service

1.Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2.Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3.Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4.Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

.jpg)

A: We have the full-automatic, semi-automatic, mobile machine for your choice. And you can according to your need to choose the corresponding production machine type.

Q2:What kind of bricks can be produced by the machine?

A: Our machine can produce the wall brick, the road tile brick with different sizes. And the different bricks can be made by changing different molds.

Q3: Can I have detailed information about your brick machine and your company, such as specifications, pictures, videos, price lists, and a catalogue?

A: Yes, surely, we would like to send all of the details information about our machines to you by email, or on WhatsApp/WeChat at our earliest time.

.jpg)