Intrudoction

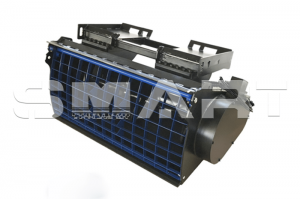

This loader-mounted mixer utilizes mature loader production technology and integrated concrete mixer production technology. The concrete mixer is modified and installed at the bucket position of the loader, utilizing the loader's hydraulic transmission device to drive the mixer. This allows for the convenience of the loader's mobility, self-feeding, and unloading advantages, while also utilizing the mixing function of the concrete mixer. Thus, this single piece of equipment can achieve multiple functions such as loading, mixing, transferring, and unloading.

Advantage

The mixing bucket loader is suitable for various construction projects, including small and medium-sized buildings, road construction, and house construction. It is capable of completing the tasks required for the project on time and in the specified quantities. Its characteristics include fast mixing speed, quick loading and unloading, high transportation speed, and long conveying distance. It easily and frequently transitions between locations, making it suitable for projects of all sizes. It offers the advantage of flexible transportation that traditional mixers lack and quick conveying and loading/unloading that mixing trucks don't possess. The mobility of this mixing bucket loader is strong, with dual-drive and dual-motor capabilities at the bucket, enabling bidirectional mixing and ensuring a more even and fine mixing of concrete, sand, and aggregate.

| Model | Rated Power (KW) |

Max Speed (km/h) |

Rated Load (kg) |

Max Load (kg) |

Bucket Capacity (m³) |

Turning Radius (mm) |

Weight (kg) |

Size |

| SN2000 | 92 | 25 | 3600 | 4000 | 2 | 4350 | 7500 | 6800*2200*3100 |

| SN1500 | 92 | 25 | 3500 | 4000 | 1.5 | 4350 | 7500 | 6800*2200*3100 |

| SN1200 | 92 | 25 | 2250 | 3000 | 1.2 | 4350 | 7000 | 6500*2100*3000 |

| SN1000 | 92 | 25 | 1870 | 2500 | 1 | 4350 | 6900 | 6400*2000*3000 |

| SN750 | 73.5 | 25 | 1650 | 2150 | 0.85 | 4350 | 6200 | 6300*2000*2950 |

| SN500 | 76 | 25 | 1400 | 1870 | 0.65 | 4350 | 6850 | 6300*2000*2950 |

A:Lead time: we have a great deal of products and spare parts in stock. On leading time we have big advantages as a manufacturer,

usually in 7-10 days after order confirmation.

Q:How do you control your quality?

A:To guarantee high quality and efficient management, we have passed CE and ISO9001 quality management system certificate. All of our products are 100% inspected before shipment. Our whole manufacturing processes are under a very serious and strict system in our company.

Q: How is the warranty period determined for the equipment?

A: The warranty period for our equipment is typically set based on industry standards and the specific product's expected lifespan. We offer a standard warranty of 12 months from the date of purchase to ensure our customers have ample coverage for any potential manufacturing defects or malfunctions. Additional extended warranty options may also be available based on the customer's preferences and the product category. Please refer to our product documentation or contact our customer service for detailed warranty information.

Q: What are the available transportation options for the products?

A:We transport the equipment by placing it in a shipping container and then arranging for shipment. This ensures safe and efficient transportation of the equipment to its destination. Please note that the specific shipping arrangements may vary based on the destination and logistics, but utilizing shipping containers is a standard practice for our transportation process. For more details on shipping and delivery, please reach out to our logistics department.

.jpg)